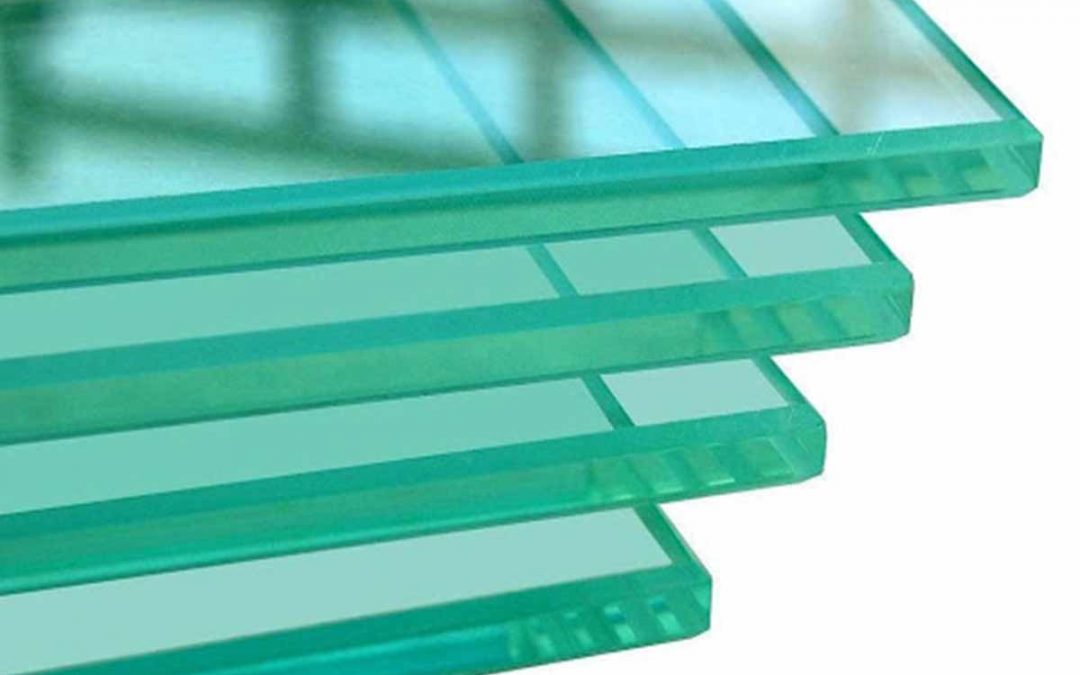

Have you ever wondered how toughened is glass made? Toughened glass is made from normal, float glass.

Toughened glass starts life as float glass. Float glass, when shattered breaks into shard like pieces and can be harmful, it is therefore unsuitable for some many glazing areas especially doors.

Before undergoing the toughening process the glass must be cut to size.

In the toughening process, the surfaces of the glass are heated in a furnace. Recommended temperatures vary but the glass reaches temperatures of over 620°C. The hot glass is then cooled rapidly by a blast of air over a period of between 3 and 10 seconds. As a result, the surfaces shrink, and (at first) tensile stresses develop on the surfaces.

As the bulk of the glass begins to cool, it contracts. The already solidified surfaces of the glass are then forced to contract, and consequently, they develop residual compressive surface stresses, while the interior zone develops compensating tensile stresses. The tension zone in the core of the glass takes up about 60% of the cross-sectional area of the glass. Compressive surface stresses improve the strength of the glass in the same way that they do in other materials

After the process the toughened glass has a greater resistance to thermal stresses and thermal shock and has improved flexural and tensile strength.

However, the following characteristics remain unchanged; • Colour, • Clarity, • Chemical composition, • Light transmission, • Hardness, • Specific gravity, • Expansion coefficient, • Softening point, • Thermal conductivity, • Solar transmittance, • Stiffness.

Contact Us On 01752 339373 for information on getting toughened glass fitted.